The productivity of a lathe is entirely contingent upon the chuck utilised, encompassing its gripping capability and its precision in maintaining concentricity.

A lathe equipped with the meticulously crafted Microturners chuck significantly enhances the lathe’s production capacity, offering a solution for achieving faster and more consistently reliable manufacturing output.

Construction:

The traditional combination of a bevel gear and scroll mechanism has been replaced with a more advanced setup: a worm and wormwheel featuring three circular cams for controlling the jaws. The wormwheel-cum-cam ring, constructed from chrome case-hardened steel, delivers exceptional wear resistance. Importantly, it efficiently absorbs and manages the entire clamping force reaction exerted by the three jaws, thereby relieving stress from the chuck body and its component parts.

Both the chuck body and the wormwheel-cum-cam ring are meticulously fashioned from steel forgings, ensuring an optimal grain flow that minimises distortion when subjected to clamping forces. Every component is generously sized and crafted from high-tensile alloy steels, with hardening and precision grinding employed as needed to meet stringent accuracy requirements. Additionally, the hard jaws are equipped with gripping serrations to securely hold the workpiece in place.

The inherent dimensional fluctuations in the workpiece’s gripping diameter are effectively managed by the ample stroke of the base jaws, obviating the need for frequent adjustments of the top jaws.

Each circular cam is accompanied by a chrome case-hardened button featuring a groove of identical radius as the cam itself. This design element significantly enlarges the pressure-bearing region on the load-transmitting surfaces. The resulting expansive bearing areas reduce stress per unit area to a minimum, preventing any potential denting of the circular cam.

Advantages:

Due to the judicious use of a relatively small number of well-designed components in the chuck, frictional losses are minimised. The inclusion of a worm, wormwheel, and circular cam provides the chuck with an exceptionally high mechanical advantage, resulting in a gripping force significantly greater than that of a scroll chuck when the same effort is applied to the chuck key. The appropriately designed cam rise, combined with the worm drive, ensures a self-locking action across the entire clamping range, guaranteeing the operator’s safety.

The top jaws are securely positioned on the base jaws through serrations ground after the jaws undergo case hardening. Adjusting the top jaws for different workpiece sizes is a swift process; it merely involves loosening two socket head screws, shifting the jaw to the suitable serration, and then re-tightening.

For Three-Jaw chucks ranging in size from 125mm to 315mm in diameter, the base jaws are equipped with serrations measuring 1.5 x 60°. For sizes ranging from 400mm to 800mm in diameter, ‘V’ serrations measuring 3/32″ x 90° are provided.

Soft Jaws:

Soft jaws, crafted from low carbon steel, find application in secondary operations. Their purpose is to securely grip finished workpiece diameters, and they are provided in a blank state. These soft jaws are designed to be reversible, allowing both ends to be utilised.

The gripping diameters are intended to be machined directly on the chuck, ensuring the precise alignment of the workpiece on the soft jaws within tight tolerances.

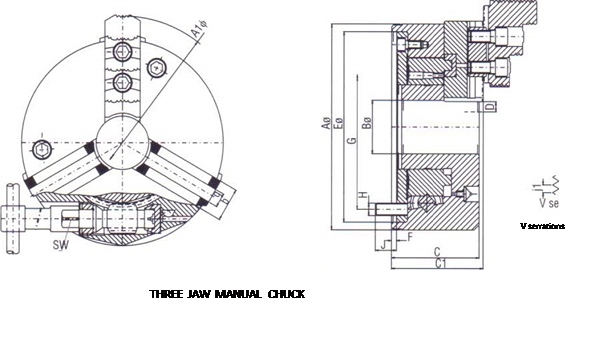

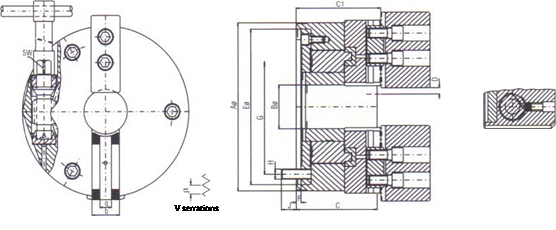

| Model | 3-Feb | 3-Mar | 3-Apr | 3-May | 3-Jun | 3-Jul | 3-Aug | Mar-22 | Mar-23 | |

|---|---|---|---|---|---|---|---|---|---|---|

| SizeØ | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 900 | |

| AØ | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 900 | |

| AIØ Max | 198 | 246 | 296 | 375 | 460 | 580 | 760 | 970 | 1090 | |

| BØ | 41 | 52 | 68 | 92 | 130 | 170 | 245 | 380 | 380 | |

| C | 83 | 87 | IOO | 113 | 116 | 126 | 147 | 161 | 161 | |

| C1 | 87 | 91 | 104 | 117 | 120 | 130 | 152 | 168 | 168 | |

| D jaw stroke | 10 | 12 | 13 | 15 | 18 | 22 | 25 | 30 | 30 | |

| E ØH6 | 150 | 185 | 235 | 300 | 380 | 460 | 580 | 710 | 710 | |

| F | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 7 | 7 | |

| G | 125 | 160 | 200 | 250 | 315 | 400 | 520 | 660 | 660 | |

| H | 2 x M12 | 3 x M12 | 3 x M16 | 3 x M20 | 3 x M20 | 3 x M24 | 3 x M24 | 3 x M30 | 3 x M30 | |

| J | 15 | 21 | 23 | 24 | 21 | 36 | 35 | 48 | 48 | |

| sw | 11 | 14 | 17 | 19 | 19 | 24 | 24 | 24 | 24 | |

| b | 30 | 35 | 38 | 45 | 50 | 50 | 60 | 60 | 60 | |

| j1 | 1.5 x 60° | 1.5 x 60° | 1.5 x 60° | 1.5 x 60° | 3/32" x 90° | 3/32" x 90° | 3/32" x 90° | 3/32" x 90° | 3/32" x 90° | |

| qH7 | 12 | 14 | 17 | 21 | 21 | 21 | 25.5 | 25.5 | 25.5 | |

| Outer Clamping | Max | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 900 |

| Min | 10 | 12 | 14 | 16 | 18 | 30 | 50 | 150 | 250 | |

| Inner Clamping | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 900 | |

| Min | 55 | 60 | 68 | 76 | 98 | 110 | 180 | 320 | 420 | |

| RPM Max. | 3000 | 2800 | 2200 | 1800 | 1400 | 1100 | 900 | 600 | 550 | |

| Weight (KG) | 12 | 19 | 35 | 58 | 110 | 180 | 307 | 490 | 600 | |

Every chuck is furnished with the following components: a set of hard jaws that can be reversed, a set of soft jaws, an allen wrench for securing the jaw screws, a chuck operating key complete with a tommy bar, and a set of chuck clamping screws.

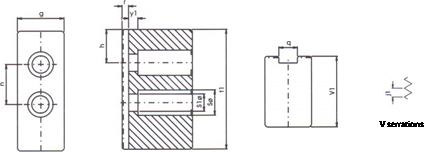

Hard Jaw Specifications

| Size | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 900 |

|---|---|---|---|---|---|---|---|---|---|

| g | 30 | 35 | 40 | 45 | 50 | 50 | 60 | 60 | 60 |

| h | 32 | 35 | 37 | 45 | 52 | 64 | 92 | 115 | 115 |

| j1 | 1.5 x 60° | 1.5 x 60° | 1.5 x 60° | 1.5 x 60° | 3/32" x 90° | 3/32" x 90° | 3/32" x 90° | 3/32" x 90° | 3/32" x 90° |

| n | 25 | 30 | 35 | 40 | 50 | 60 | 65 | 85/70* | 85/70* |

| qH7 | 12 | 14 | 17 | 21 | 21 | 21 | 25.5 | 25.5 | 25.5 |

| r | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| sØ | 17.5 | 19 | 23 | 25 | 25 | 25 | 31 | 31 | 31 |

| s1Ø | 11 | 13 | 15 | 17 | 17 | 17 | 21 | 21 | 21 |

| t1 | 70.2 | 83 | 95 | 112 | 132 | 163 | 197 | 246.5 | 246.5 |

| v1 | 46 | 53 | 58 | 63 | 73 | 87 | 91 | 98 | 98 |

| y1 | 6.5 | 7 | 8 | 8 | 8 | 8 | 12 | 12 | 12 |

* = has 3 clamping holes

Specifications listed in blue are special

Specifications listed in blue are special

Each chuck is provided with the following components: a set of soft jaws, an allen wrench for tightening the jaw screws, a chuck operating key that includes a tommy bar, and a set of chuck clamping screws.

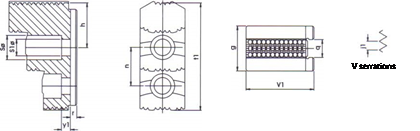

Soft Jaw Specifications For Two & Three Jaw Chucks

| Size | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| g | 2 jaw | 55 | 55 | 60 | 65 | 78 | 78 | 80 | - |

| 3 jaw | 35 | 35 | 40 | 45 | 50 | 50 | 60 | 60 | |

| h | 22.5 | 25 | 29.5 | 30 | 40 | 40 | 70 | 70 | |

| j1 | 1.60° | 1.5 x 60° | 1.5 x 60° | 1.5 x 60° | 3/32” x 90° | 3/32” x 90° | 3/32” x 90° | 3/32” x 90° | |

| n | 25 | 30 | 35 | 40 | 50 | 60 | 65 | 85/70* | |

| qH7 | 12 | 14 | 17 | 21 | 21 | 21 | 25.5 | 25.5 | |

| r | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| s Ø | 16.75 | 19 | 23 | 25 | 25 | 25 | 31 | 31 | |

| s 1Ø | 10.5 | 13 | 15 | 17 | 17 | 17 | 21 | 21 | |

| t1 | 80 | 90 | 110 | 130 | 160 | 190 | 225 | 275 | |

| v1 | 53 | 53 | 58 | 63 | 76 | 87 | 91 | 98 | |

* = has 3 clamping holes

Specifications listed in blue are special